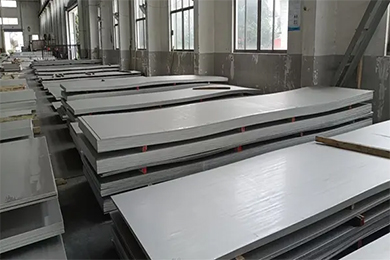

Stainless Steel

Stainless Steel

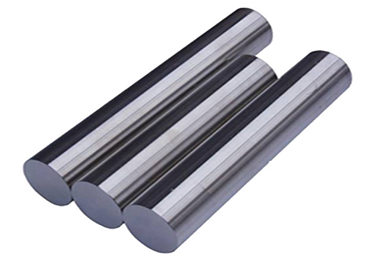

High Speed Steel

High Speed Steel

Tool Steel

Tool Steel

Special alloy steel, high temperature alloy steel, and high temperature resistant special steel are widely used as superior raw materials for fasteners for automobiles, ships, aviation and other large-scale machinery and equipment industries and fasteners for furniture decoration..

The introduction of advanced production technology, supporting Taiwan automatic heat treatment equipment and German phosphating production line, further improve and expand the product quality and scope.

Our special steel is sold to Europe, North America, South America, and Asia Malaysia, Indonesia, Thailand, Pakistan, Colombia, Paraguay and many other countries and regions.

Our main products are: Stainless /High Speed/Tool /Mould /BEARING /ALLOY STRUCTURAL/ GEAR /NICKEL-BASED STEEL

After years of unremitting efforts and market baptism, the company has developed into an old-fashioned enterprise in the special steel industry.

Steelfirst supply to AISI steel grades and AISI equivalent grades. In addition we are stockists and suppliers of Stainless Steel with precipitation hardening 17/4PH, FV520B, Duplex UNS S31803 and Super Duplex UNS S32760 grades. Austenitic, martensitic and ferritic specifications stocked in a large range of shapes and sizes. We are also steel suppliers of austenitic 11 to 14% High Manganese Steel, which is a work hardening steel grade.. With a wide stock range, you'll find Tool Steel specifications, suitable for cold work, hot work, and plastic mould applications. Also ground Tool Steel products including Silver Steel and Ground Flat Stock. Tool Steel can be supplied to European Standards such as Werkstoff and DIN Specifications. We also supply to AISI steel grades and AISI equivalent grades.

Read MoreWe have many years experience of special steel sale.

DIN-AL 99.0 JIS-A1050TE CNS-5454 JIS-S9CK

GB-LF21 DIN-ALCUMG2 JIS-A5254P JIS-A1100TW

JIS-SEV245 DIN-GTS-45-06 JIS-A1070 TD JIS-A5154TD

JIS-TP270/TR270 ASTM-GR.4 DIN-G-CUZN35AL1 CNS-HBSC4

DIN-GGG-NI-CRNB20-2 JIS-FCDANI35 CNS-FCMW330 JIS-TTH340

ASTM-NO. 20 ASTM-NO.60 JIS-FCD400-15 JIS-FCD 700-2

JIS-SS490 DIN-GGL-NICU-CR15-6-2 DIN-G-CUSN5ZNPB JIS-SNB21-2

ASTM-GR.WCA DIN-ALMG4.5MN CNS-SCC5A DIN-RST34-2

DIN-17MN4 ASTM-C84400 DIN-G-CUZN15SI4 JIS-MP1

CNS-FCMB310 DIN-X12CR-NI17-7 JIS-SUS309S CNS-ZDC1

CNS-SFNCM80 JIS-SFNCM-1030 CNS-SMNC420 GB-KMTBCR15-MO2-GT

DIN-16MNCR5 JIS-TTP480 CNS-SPV235 DIN-G-CUZN15

CNS-SLA325A ASTM-GR.65 CNS-SL3N255 JIS-SUS316

CNS-SL3N255 DIN-TSTE 315 JIS-SCMV2-1 CNS-SFCM70

Carbon Steel Plates for Pressure Vessels for Low Temperature Service Nickel Plates for Pressure Vessels for Low Temperature Service

Heat-Resisting Stainless Carbon and Alloy Forgings for Pressure Vessels for Low Temperature Service

Chromium-Molybdenum Alloy Plates for Pressure Vessels Chromium Molybdenum Forgings for General use

Aluminum and Aluminum Alloy Rods, Bars and Wires(Extruded) Rolled for General Structure

Nickel Chromium Molybdenum Forgings for General use Carbon Castings Steel Castings for Welded Structure

High Tensile Strength Carbon Castings and Low Alloy Steel Castings for Structur High Manganese Casting

Castings for High Temperature and High Pressure Service Steel Castings for Low Temperature and High Pressure Service

Stainless Castings Heat Resisting Castings Gray lron Castings Spheroidal Graphite lron Castings

Austenitic Cast lron of Flake Graphite Austenitic Cast lron of Spheroidal Graphite Abrsion Resisting Cast lron Low Alloy and High Alloy Grade

Blackheart Malleable lron Castings White Heart Malleable lron Castings Manganese Chromium Steels for Machine Structural use

Alloy Bolting Materials for High Temperature Service Alloy Bars for Special Application Bolting Materials

Zinc Alloy Castings Titanium and Titanium Alloy Sheets,Plates and Strips Titanium and Titanium Alloy Seamless Pipes

Titanium and Titanium Alloy Tube for Heat Exchangers Titanium and Titanium Alloy Rods and Bars

Bronze Castings Phosphor Bronze Castings Leaded Bronze Castings Corrosion-Resisting Stainless

Brass Castings High Strength Brass Castings Aluminum Bronze Castings Silicon Bronze Castings

Magnesium Alloy Sheets Plates Magnesium Alloy Bars Steel Plates for Pressure Vessels Steel Sheet/Plates and Strips for Gas Cylinders

Carbon Plate for Pressure Vessels for Intermediate and Moderate Temperature Service

Mn-Mo and Mn-Mo-Ni Alloy Plates for Boilers and Other Pressure Vessels

Mn-Mo and Mn-Mo-Ni Alloy Plate Quenched and Tempered for Pressure Vessels

High Strength Plates for Pressure Vessels for Intermediate and Moderate Temperature Service

Pearlitic Malleable lron Castings Aluminum and Aluminum Alloy Drawn Pipes and Tubes

Aluminum and Aluminum Alloy Extruded Pipes and Tubes Aluminum and Aluminum Alloy Welded Pipes and Tubes

Aluminum and Aluminum Alloy Sheets, Plates and Strips Aluminum Shapes Extruded Carbon for Machine Structural use

Alumium and Aluminum Alloy Forgings Carbon Tool Steels Alumium and Aluminum Alloy Castings

X12Cr MoS17 DIN

X12Cr Ni17 7 DIN

X12Cr Ni188 DIN

X12CrS13 DIN

X15 ASTM

X20Cr13 DIN

X20Cr Ni17-2 DIN

X30Cr13 DIN

X65Cr Mo14 DIN

X90Cr MoV18 DIN

X105Cr Mo17 DIN

XM7 ASTM

XM7 CNS

XM15J1 CNS

XM27 ASTM

XM27 CNS

Y1Cr13 GB

Y1Cr17 GB

Y1Cr18 Ni9Se GB

Y3Cr13 GB

00Cr12 GB

00Cr17Ni 13Mo2N

00Cr17Ni 14Mo2

00Cr18 Ni10N

00Cr18Ni 14Mo2Cu2

00Cr19 Ni10-GB

00Cr19Ni 13Mo3

00Cr26Ni 5CrMo2

00Cr27Mo GB

00Cr30 Mo2 GB

0Cr13-GB

0Cr17Ni 4Cu4Nb GB

0Cr17 Ni7A1 GB

0Cr17Ni-12Mo2N-GB

0Cr18Ni-9Cu3-GB

0Cr18Ni9 GB

0Cr18Ni-11Nb GB

0Cr18 Ni11Ti GB

0Cr18Ni12 Mo2Cu2-GB